🌟 核心卖点速览 (Key Features – Bullet Points)

⚙️ Engineered for Industrial Reliability

Designed to meet the rigorous demands of modern machinery, offering superior performance over traditional brushed motors.

📉 Zero Maintenance & Long Life: Eliminates the need for carbon brush replacement. With no mechanical commutator sparking or wear, our motors offer a lifespan exceeding 50,000 hours.

⚡ High Efficiency & Energy Saving: Featuring rare earth neodymium magnets, these motors achieve efficiencies of up to 85-90%, reducing heat generation and lowering your operational energy costs.

🛡️ Robust & Protected: Available in IP54 ratings, our motors are built to withstand harsh industrial environments, including dust, oil, and water exposure.

🎛️ Precision Control: Compatible with a wide range of PWM speed controllers and drivers. Offers smooth speed regulation and excellent low-speed torque for precise machinery operation.

🔧 Customization Expertise: We support OEM/ODM services. Customize the voltage, speed, shaft configuration, to perfectly fit your specific machine design.

Why choose our brushless DC motor?

Designed to meet the rigorous demands of modern machinery, offering superior performance over traditional brushed motors.

📉 Zero Maintenance & Long Life: Eliminates the need for carbon brush replacement. With no mechanical commutator sparking or wear, our motors offer a lifespan exceeding 50,000 hours.

⚡ High Efficiency & Energy Saving: Featuring rare earth neodymium magnets, these motors achieve efficiencies of up to 85-90%, reducing heat generation and lowering your operational energy costs.

🛡️ Robust & Protected: Available in IP54 ratings, our motors are built to withstand harsh industrial environments, including dust, oil, and water exposure.

🎛️ Precision Control: Compatible with a wide range of PWM speed controllers and drivers. Offers smooth speed regulation and excellent low-speed torque for precise machinery operation.

🔧 Customization Expertise: We support OEM/ODM services. Customize the voltage, speed, shaft configuration, to perfectly fit your specific machine design.

🛠️ 应用场景 (Applications)

🏭 Industrial Automation: Conveyor systems, robotic arms, CNC routers.

🏥 Medical Equipment: Hospital beds, dental chairs, fluid pumps.

🖨️ Printing & Packaging: Label printers, film winding machines, packaging sealers.

🌬️ HVAC & Ventilation: High-speed fans, exhaust systems, air compressors.

🚗 Special Vehicles: Electric sweepers, golf carts, forklift steering systems.

The Smart Choice for Modern Machinery

In the competitive world of industrial automation and equipment manufacturing, downtime is the enemy. Traditional brushed motors often fail due to brush wear, especially in dusty or high-speed applications.

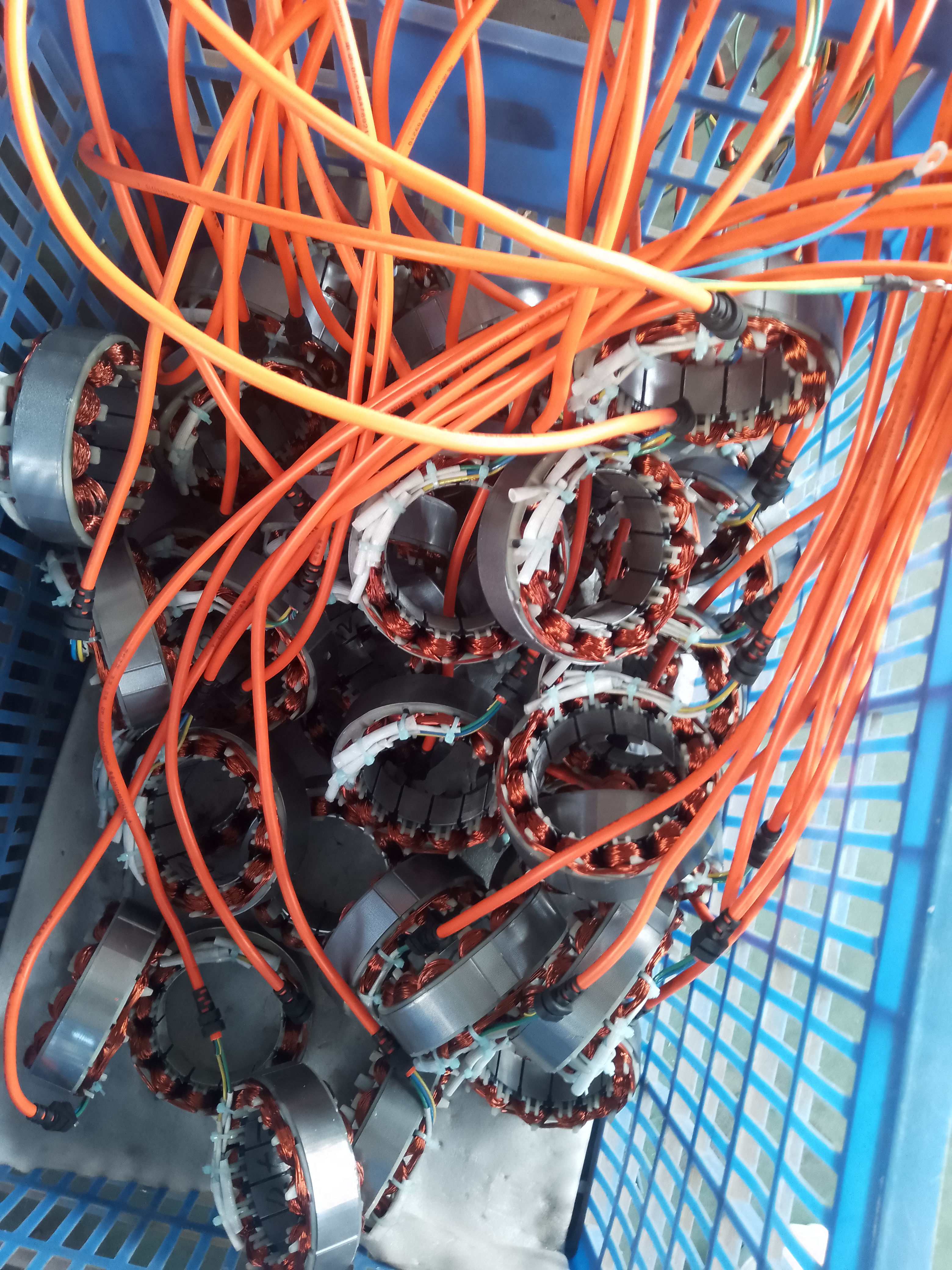

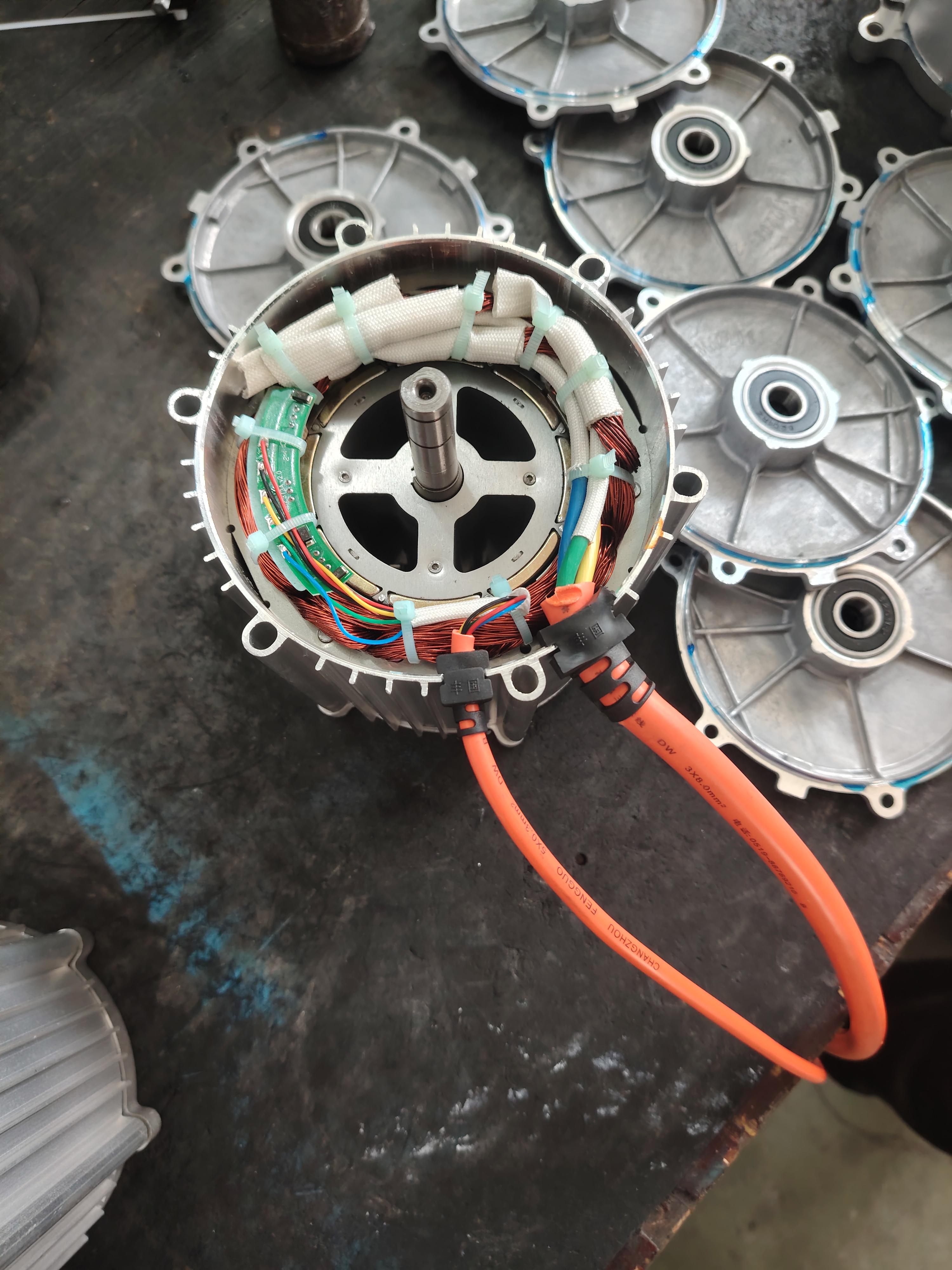

Our Permanent Magnet Brushless DC (BLDC) Motors are the intelligent solution. By replacing physical brushes with electronic commutation, we deliver a motor that is not only more powerful but virtually maintenance-free.

- Versatile Power for Diverse Applications

Whether you are building packaging machines, medical devices, textile machinery, or automated guided vehicles (AGVs), our wide range of frame sizes (from 28mm to 120mm) and power ratings ensures you find the perfect match. - Built for Tough Conditions

The robust aluminum housing provides excellent heat dissipation, while the fully sealed construction protects the internal components from the ingress of dust and water. This makes our motors ideal for use in food processing, outdoor equipment, and factory floors. - Seamless Integration

We understand that every machine is different. That’s why our standard motors are designed with international mounting standards (such as IEC B14, B5) in mind, ensuring easy installation and replacement.

We support OEM/ODM services. Customize the voltage, speed, shaft configuration, to perfectly fit your specific machine design

Engineering Support: Our team of experienced engineers provides technical support from the design phase through to after-sales service.

Product Parameters

| Parameter category | Common specifications |

|---|---|

| Model | 120 |

| Rated voltage | 24 v/48 V/60 V/72 V |

| Rated Power | 350 w-1800 w |

| No-load Speed | 3000 rpm/1500 rpm |

| Motor type | BLDC MOTOR |

| motor shaft | Single key shaft motor |

| polar pair | 4 |

| position sensor | Hall (5-pin) |

| Protection level | IP54 |

| insulation class | F |

| working system | S2 60min |

| Control method | Square wave control |

Product working environment

| Storage temperature range | -40 ℃~85 ℃ |

| Working temperature range motor | -40 ℃~55 ℃ |

| humidity | 0~95% |

A: Long lifespan and maintenance free: Mechanical equipment typically requires 24-hour continuous operation. The carbon brushes of brushed motors are vulnerable parts that require regular shutdown for replacement, while brushless motors have no mechanical wear and have a lifespan of tens of thousands of hours, significantly reducing downtime and maintenance costs.

No electromagnetic interference: When the brushed motor changes direction, sparks will be generated, which will interfere with the precision sensors or PLC control systems of mechanical equipment. The brushless motor adopts electronic commutation, which has better electromagnetic compatibility (EMC) and more stable operation.

High efficiency: Brushless motors typically have an efficiency of over 85% and generate minimal heat, making them particularly important for enclosed or temperature sensitive mechanical equipment such as medical devices and precision instruments.

No. Permanent magnet brushless DC motor (BLDC) must be used in conjunction with an electronic controller (Driver/Controller).

Reason: There is no mechanical commutator inside the motor, and the controller needs to accurately control the energizing sequence of the stator coils based on the rotor position (detected by Hall sensors or back electromotive force).

Suggestion: We provide matching PWM speed control controllers or vector controllers (FOC). Please choose them together when purchasing, or ensure that your existing controller matches the Hall signal angle (60 ° or 120 °) of the motor.

A: IP54: Partially dust-proof (Level 5) and capable of partially preventing low-pressure water jets from any direction. Suitable for most factory environments, it can prevent coolant splashing and dust accumulation.

Tip: Our industrial motors come standard with double-sided oil sealed bearings to further prevent grease leakage and external contaminants from entering.

A: Support customization (OEM/ODM). We understand that the requirements of each mechanical equipment are unique.

Customizable content:

Electrical parameters: voltage, speed, torque, power.

Mechanical structure: shaft diameter, shaft length, flange hole spacing, wiring method.

Function extension: Install brakes and encoders for position feedback, gearbox, etc.

Process: Please provide your drawings or detailed parameter requirements, and our engineers will provide you with a customized solution within 24 hours.

A: The noise is extremely low. Due to the absence of mechanical noise caused by friction between brushes and commutators, our motor operates very quietly.