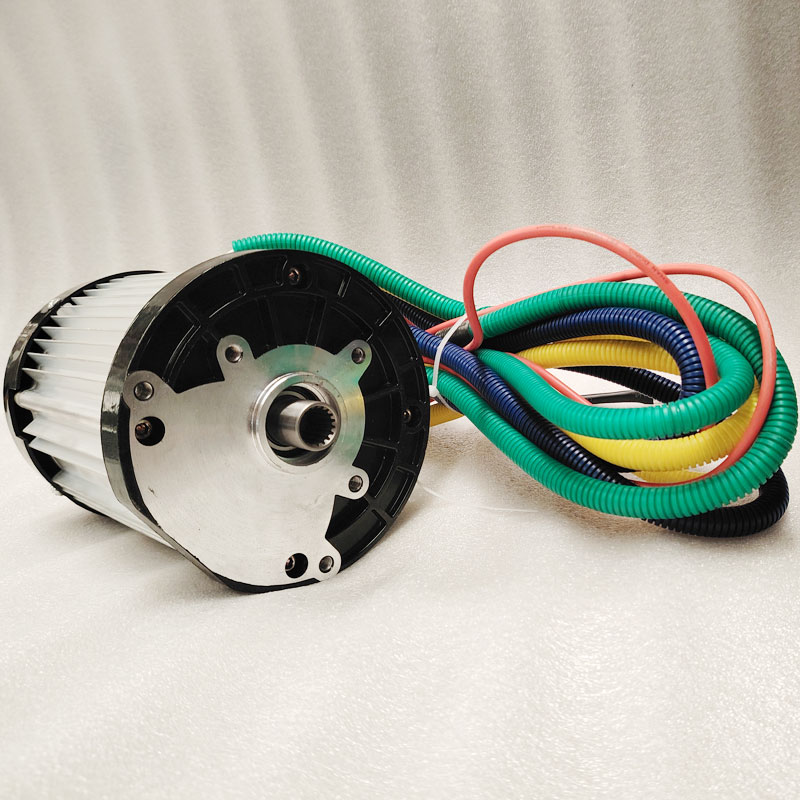

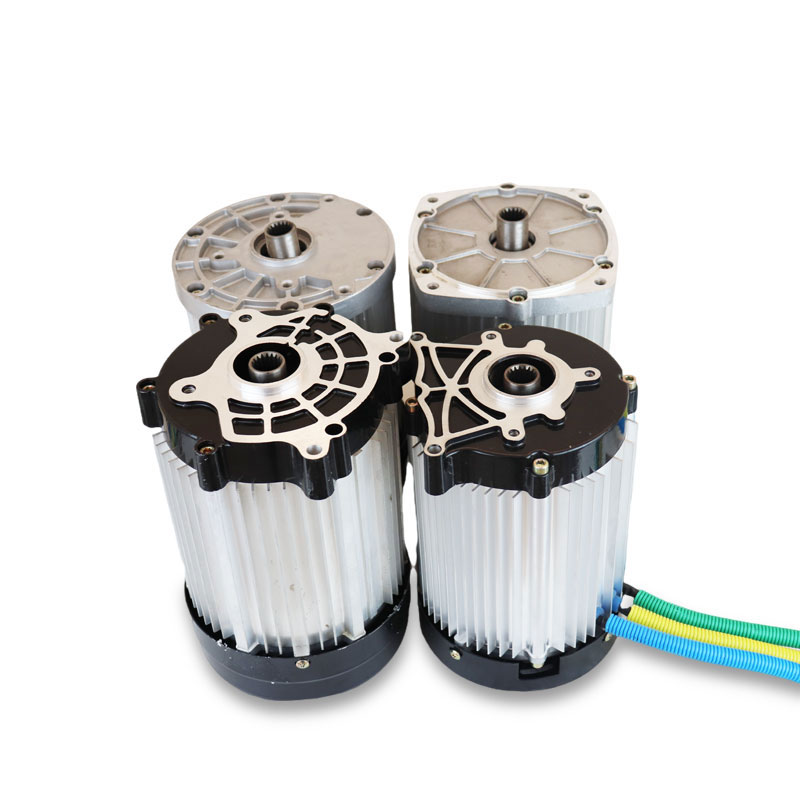

Our 2500W to 4000W Permanent Magnet Brushless DC (PM BLDC) motors are specially designed for electric tricycles, electric cargo vehicles, and agricultural machinery.

When used in conjunction with a differential gearbox, this product series features a high-torque reduction design and an aluminum alloy housing, offering the advantage of reliable performance. It is perfectly suited for applications in the market that require heavy loading, low speed, and continuous operation.

Key Specifications

Application Type: Traction Motor

Power Range: 2500W / 3000W / 4000W

Rated Voltage: 48V / 60V / 72V / 80V

Motor Type: Permanent Magnet Brushless DC Motor (PM BLDC)

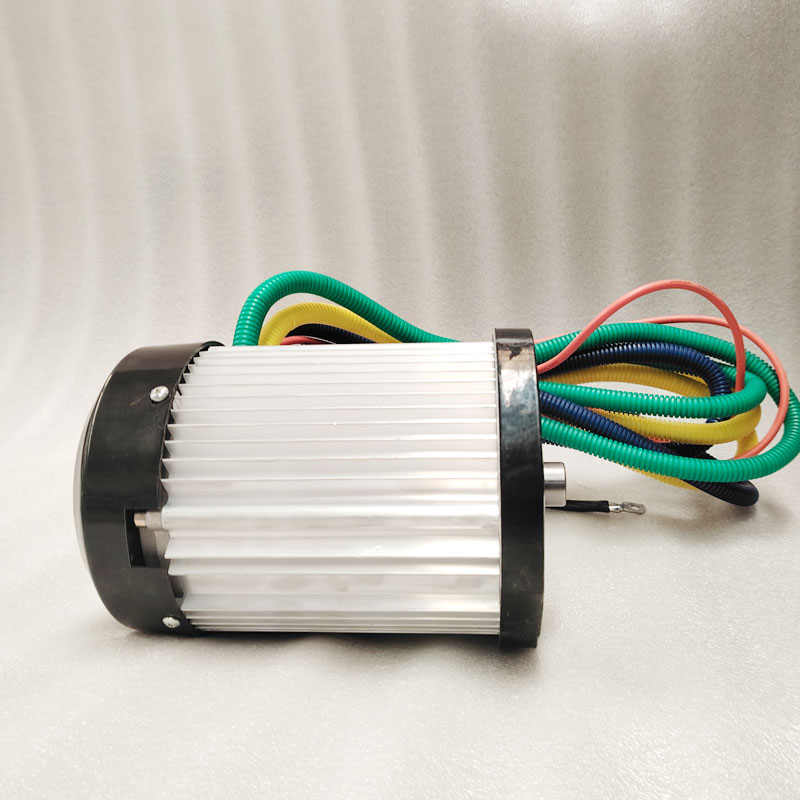

Cooling Method: Air Cooled

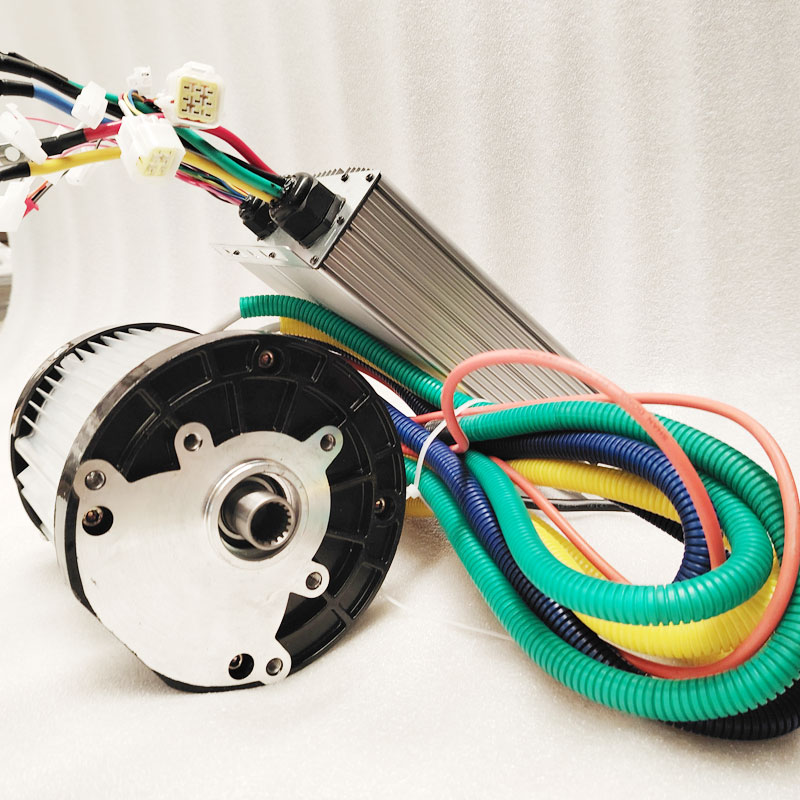

Drive Type: Geared / Reduction Drive

Housing Material: Aluminum Alloy

Output Shaft: Spline Shaft (customizable)

Key Features & Benefits

High Torque Output: Optimized for heavy loads, hill climbing, and poor road conditions

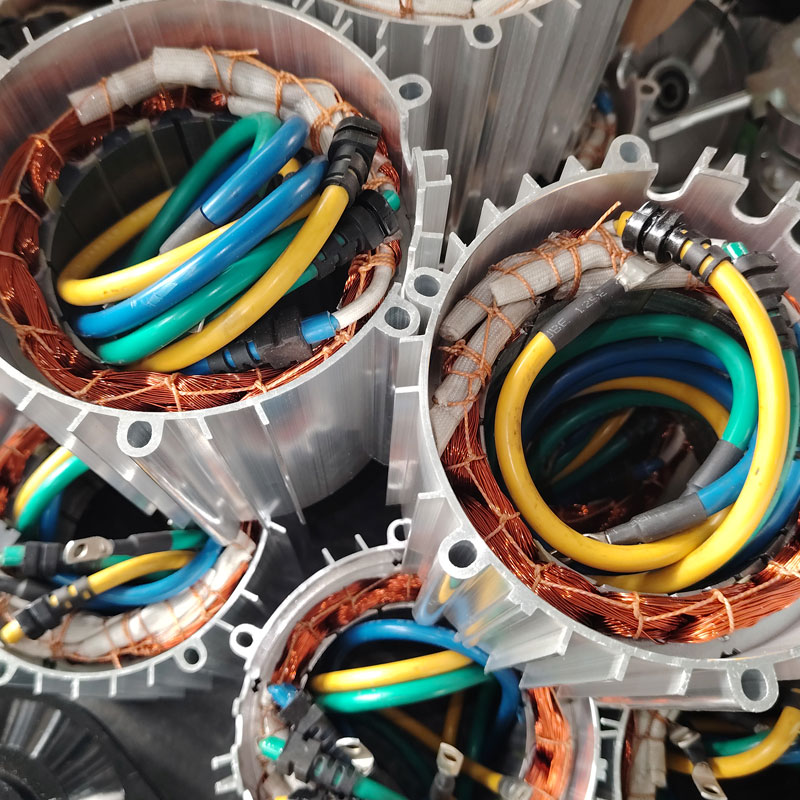

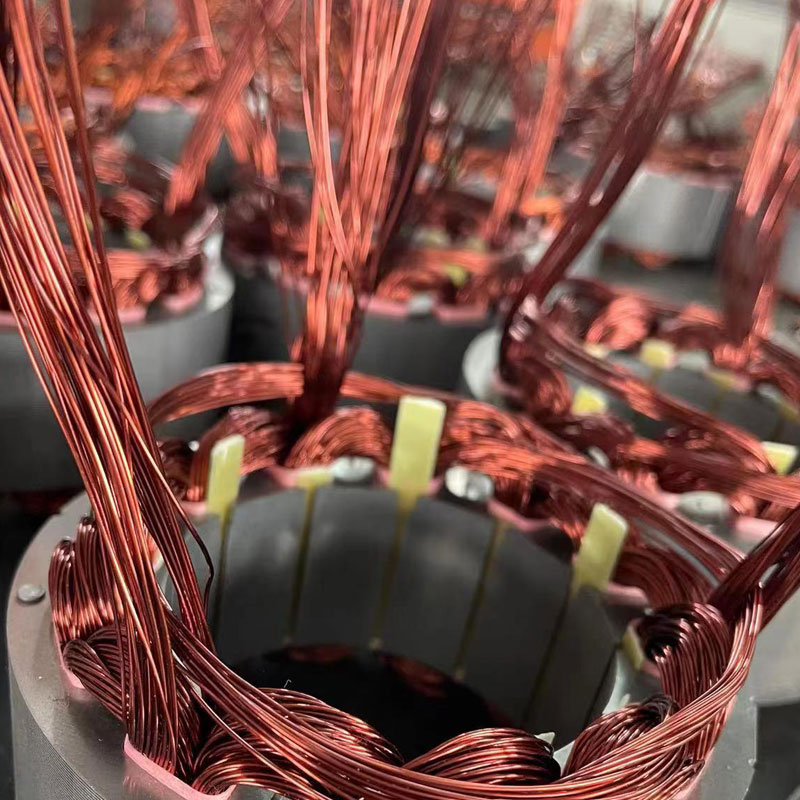

Permanent Magnet Rotor: High efficiency and stable torque at low speed

Geared Reduction Design: Improves load capacity and vehicle start-up performance

Excellent Heat Dissipation: Aluminum housing suitable for hot climates

Reliable & Durable: Designed for continuous-duty operation

Low Maintenance: Simple structure, easy for local service

Robotic tracked chassis (UGV/AGV/UGV platforms)

Crawler inspection robots

Firefighting and rescue robots

Agricultural mini tracked vehicles

Industrial crawler carriers

All-terrain tracked chassis systems

Engineering and construction crawler bases

Power Selection Recommendation

2500W–3000W: Standard cargo electric tricycles and utility vehicles

4000W: Heavy-duty agricultural machinery and farm utility vehicles

Our engineers can recommend the most suitable motor based on load, speed, and operating conditions.

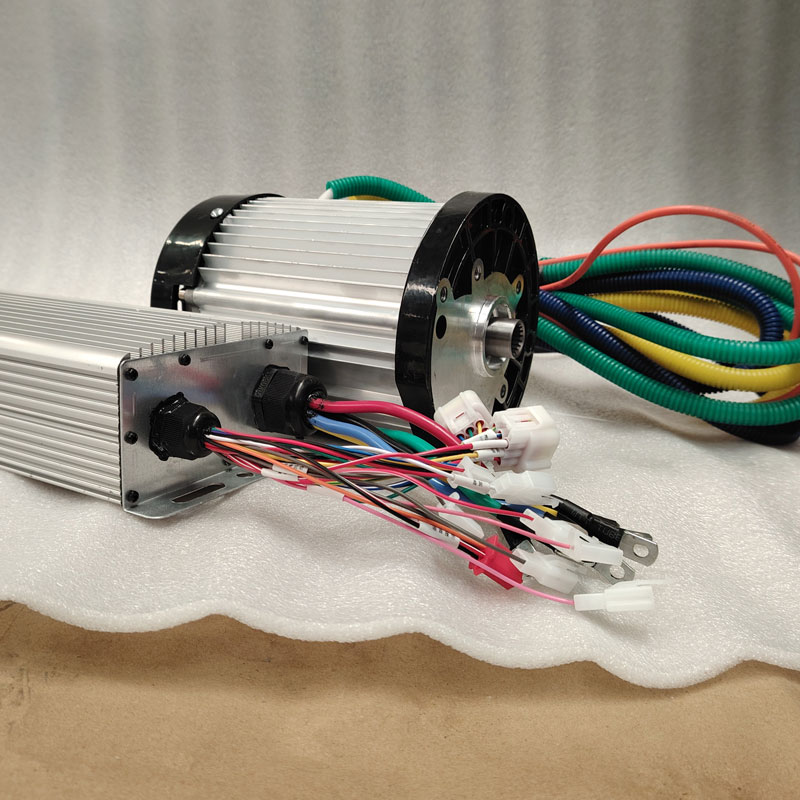

Compatible Controllers

We provide matched BLDC motor controllers for each power level and voltage option. Controller parameters can be adjusted to meet different load requirements and driving conditions.

OEM & Customization Service

We support OEM and ODM services, including:

- Power and voltage customization

- Shaft type and mounting design

- Speed and torque tuning

- Controller matching

- Branding and packaging customization

We work closely with electric vehicle and agricultural machinery manufacturers worldwide.

Technical Specifications

| Parameter | Specification | Parameter | Specification |

| Model | 140 | Rated voltage | 48 v/60 v/72 v/80 v |

| rated voltage | 2500 W-4000 W | Rated speed | 3200rpm |

| Magnetic steel grade | 38 H | Rotor height | 70 mm~100 mm |

| Motor Shaft | Internal spline, 18 teeth | Motor color | silver, black |

| position sensor | Hall (5-pin) | thermal classification | F |

| Motor type | brushless motor | Protection level | IP54 |

| Control waveform | Square wave control | working system | S2 60min |

| polar pair | 4 |

Product working environment

| Storage temperature range | 40℃~85℃ |

| Working temperature range | Motor: -40 ℃~55 ℃ |

| humidity | 0~95% |

A: These permanent magnet BLDC motors are mainly designed for electric tricycles, electric cargo tricycles, and agricultural machinery, such as farm utility vehicles, mini tractors, and electric agricultural equipment.They provide high torque at low speed, making them ideal for heavy-load and continuous-duty applications.

A: We offer a full power range from 1000W to 4000W, including:

1000W / 1500W – light-duty electric tricycles

2000W / 3000W – cargo tricycles and utility vehicles

4000W – heavy-duty agricultural machinery

Each power rating can be optimized according to load and working conditions.

A: Standard voltage options include:

48V

60V

72V

80V

Custom voltage solutions are also available for OEM projects.

A: Yes. The motor is designed for industrial and vehicle-grade use, featuring:

Aluminum alloy housing for efficient heat dissipation

Permanent magnet rotor for stable torque output

Air-cooled structure for continuous operation

It is suitable for long working hours in farm and cargo applications.

A: Yes. We can supply matched BLDC motor controllers according to:

Motor power

Voltage

Load requirement

Application scenario

This ensures optimal performance and system stability.

A: Absolutely. We provide OEM and ODM services, including:

Power and voltage customization

Shaft type and mounting design

Speed and torque tuning

Labeling and packaging

We have extensive experience working with electric vehicle and agricultural equipment manufacturers.

A: MOQ depends on the motor model:

Standard models: low MOQ

Custom OEM models: MOQ based on specification

Please contact us with your required power and application for details.

A: Our motors can be supplied with commonly required certifications such as CE, and other certifications can be supported upon request depending on the target market.

A: Standard models: 15 working days

OEM / customized motors: 30 working days

Exact lead time depends on order quantity and customization level.

A: To select the correct BLDC motor, please provide:

Vehicle type

Load capacity

Required speed

Battery voltage

Working conditions

Our engineering team will recommend the most suitable motor solution.

A: Simply send us your power requirement (1000W–4000W), voltage, and application, and our sales team will respond with a detailed quotation and technical proposal.