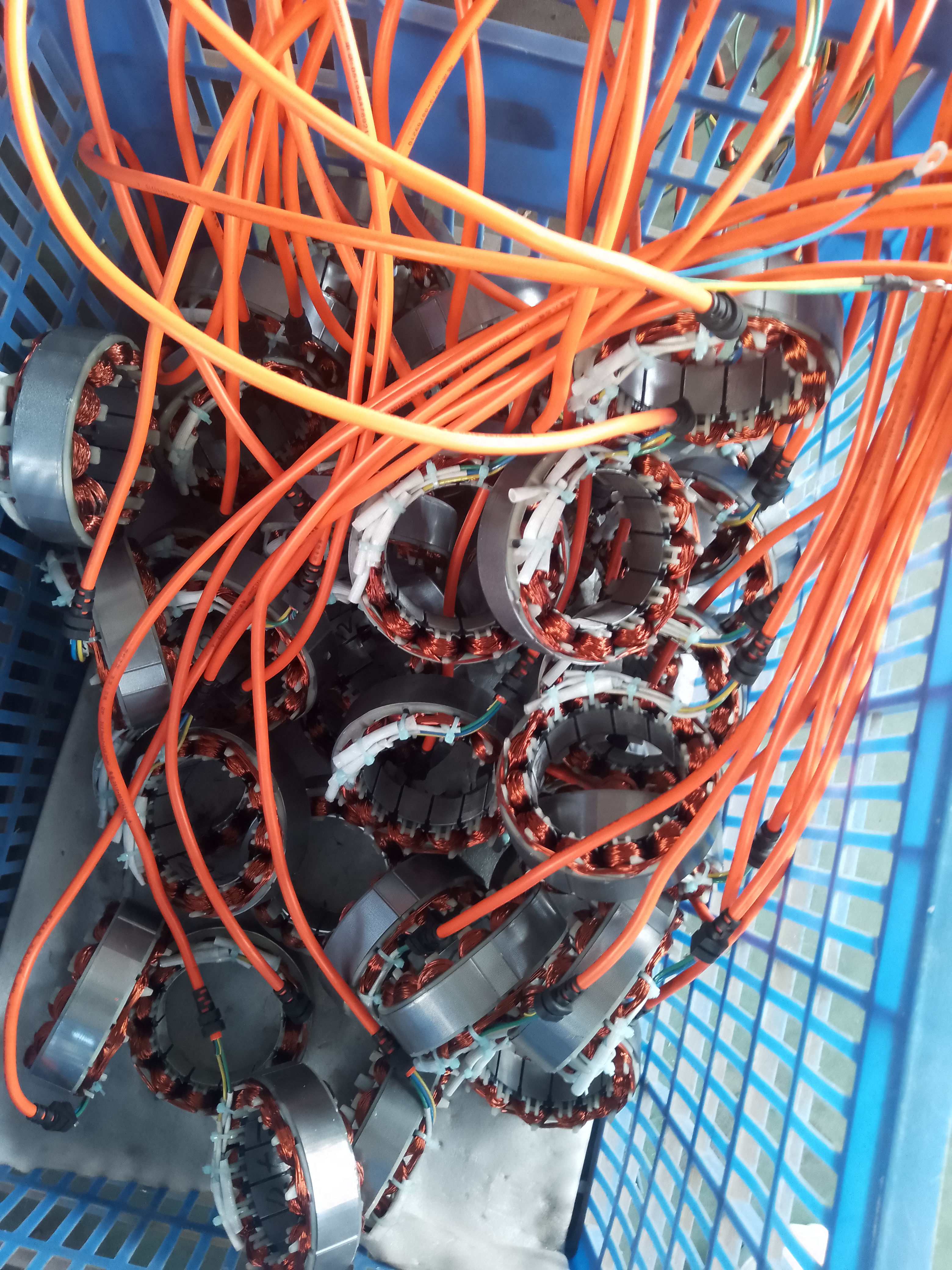

Efficient permanent magnet brushless DC gear motor (350W-1800W, 24V/48V/60V/72V) for electric tricycles and industrial automation. High torque, low noise, long lifespan, and reliable performance. Very suitable for electric tricycles, electric bicycles, golf carts, robot joints, and smart home devices. OEM/wholesale available – factory direct price.

Core Advantages

High-Efficiency Permanent Magnet Design

Adopt high-performance permanent magnet material, significantly improve energy conversion efficiency, reduce power consumption, and ensure strong power output in a compact size.

Maintenance-Free Brushless Technology

The brushless DC design eliminates friction wear, avoids carbon powder pollution, and extends the service life to more than 5 times that of traditional brushed motors, achieving zero maintenance cost.

Stable Torque Output

The integrated planetary gear reducer provides high torque at low speed with minimal backlash (<0.1mm), ensuring stable operation when starting and loading.

Ultra-Compact & Mounting Friendly

The aluminum alloy shell is small and light. The built-in mounting bracket makes it easy to install on various equipment.

Wide Voltage Adaptability

It supports 12V/24V/48V/60V/72V DC input and can be customized for special voltages to meet the power needs of different application scenarios.

🏭 Application scenarios

Industrial automation: driving conveyor belts, robotic arms, and packaging machinery.

Intelligent logistics: electric AGVs, sorting robots, and electric forklifts.

Other fields: electric tricycles, electric bicycles, textile machinery, climbing machines, etc.

OEM/ODM customization available

High-strength materials and reinforced motor housing

Suitable for heavy-duty commercial and military-grade usage

Stable performance on mud, sand, slopes, gravel, and rough terrain

Direct factory supply with competitive pricing

Technical Specifications

| Parameter | Specification | Parameter | Specification |

| Model | 120 | Rated voltage | 24 v/48 v/60 v/72 v |

| rated voltage | 350 W-1800 W | Rated speed | 500 rpm |

| peak torque | 1:6 | Rotor height | 25 mm~80 mm |

| Magnetic steel grade | 38 H | Motor color | silver, black |

| axis | sprocket | thermal classification | F |

| position sensor | Hall (5-pin) | Protection level | IP54 |

| Motor type | brushless motor | working system | S2 60min |

| motor shaft | Single key axis | polar pair | 4 |

Product working environment

| Storage temperature range | 40℃~85℃ |

| Working temperature range | Motor: -40 ℃~55 ℃ |

| humidity | 0~95% |

A:It is an integrated assembly combining a Permanent Magnet BLDC motor and a gearbox. The motor provides high-efficiency electronic commutation, while the gearbox (planetary or spur type) reduces output speed and multiplies torque. This combination delivers high torque at low speeds, precise control, and a long service life, making it ideal for applications like electric tricycles, AGV carts, and industrial automation.

A: Our BLDC gear motors offer significant improvements:

Longer Lifespan: No brushes to wear out (typically 5,000+ hours vs. 2,000 hours for brushed).

Higher Efficiency: 80-90% efficiency reduces heat and energy costs.

Zero Maintenance: No need to replace carbon brushes.

Higher Torque: The gearbox provides high starting torque, perfect for heavy loads.

Clean Operation: No sparks or carbon dust, suitable for sensitive environments.

A: The reduction ratio determines your output speed and torque.

A: We offer a wide range to match global standards:

Voltage: 12V, 24V, 36V, 48V, 60V, and 72V DC.

Power: From 350W micro-motors to 1800W high-power models.

Customization: We can design motors to meet your specific voltage and power requirements.

A:Wiring typically involves two connectors:

1. Power Connection: Connect the motor’s 3-phase wires (usually yellow, green, blue, or labeled U/V/W) to the controller’s motor output terminals.

2. Hall Sensor Connection: Connect the 5-wire Hall plug (Red: +5V, Black: GND, Yellow/Green/Blue: Signals) to the controller.

Note: Always check the wiring diagram specific to your model. Reversing power polarity can damage the motor.

A: This is usually caused by a phase sequence error.

Solution: Try swapping any two of the three main power wires (U, V, W). This will change the rotation direction and often eliminate the vibration.

A: Yes. The speed is controlled by the driver/controller.

PWM Signal: Most controllers accept a PWM signal (0-5V) for precise speed regulation.

Voltage Adjustment: Speed is also proportional to input voltage (e.g., a 48V motor will run slower at 36V).

A: Please follow these steps:

1. Check Power: Ensure the battery voltage matches the motor rating (e.g., don’t use a 24V battery on a 48V motor).

2. Check Connections: Ensure all connectors (power and signal) are securely plugged in.

3. Check Throttle: Verify the throttle/handlebar switch is working and sending a signal to the controller.

4. Overload Protection: If the load is too heavy, the controller may cut off power. Reduce the load and restart.

A: Our standard motors have an IP54 rating, protecting against dust and splashing water. They are suitable for outdoor use in electric vehicles.

Yes, we specialize in customization.

Custom Specs: We can modify voltage, power, shaft dimensions (length, diameter, keyway), and housing length.

Brand: We provide OEM services for laser marking printing and customized private labels.

MOQ: Sample orders are welcome. Custom OEM MOQ varies by complexity (typically 50-500 pcs). Contact us for a quote.

A:We provide a standard 12-month warranty from the date of shipment.

Coverage: Defects in materials and workmanship under normal use.

Exclusions: Damage caused by improper installation, overloading, or unauthorized disassembly.

A:Samples: Sent via express carriers (DHL, UPS, FedEx) for delivery within 3-7 days.

Bulk Orders: Shipped by air freight (7-12 days) or sea freight (20-40 days) to save costs.