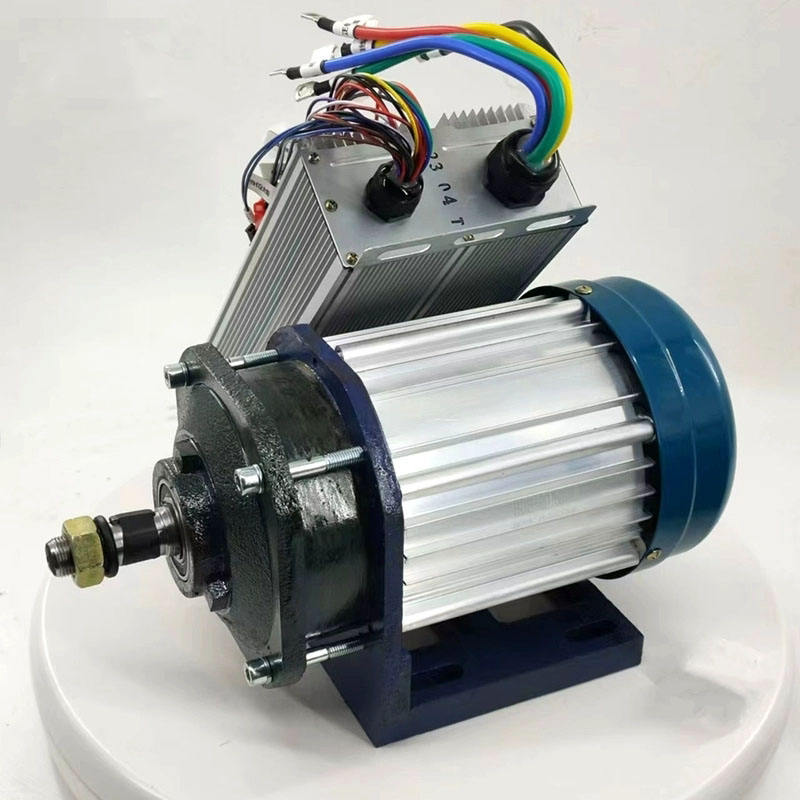

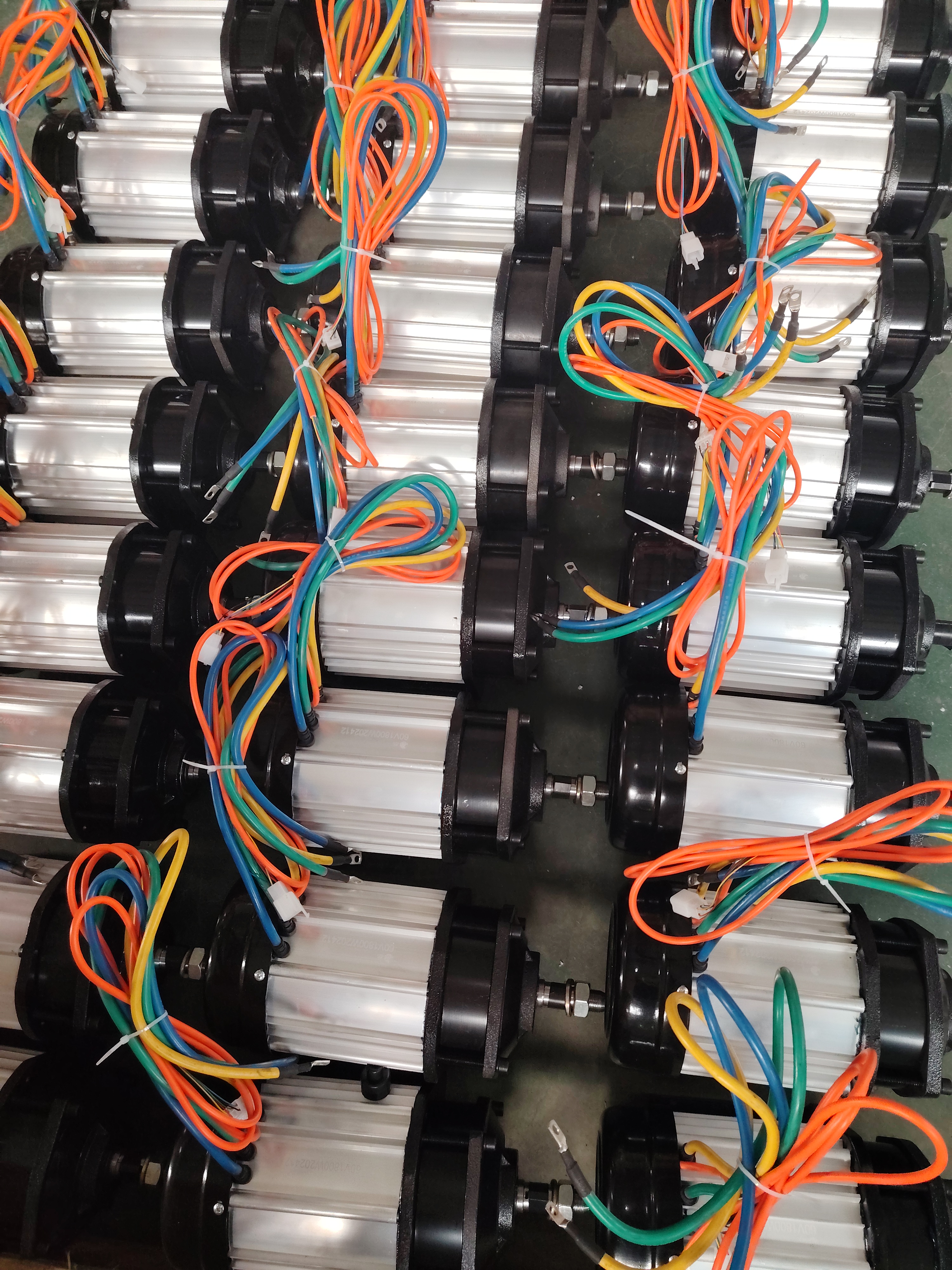

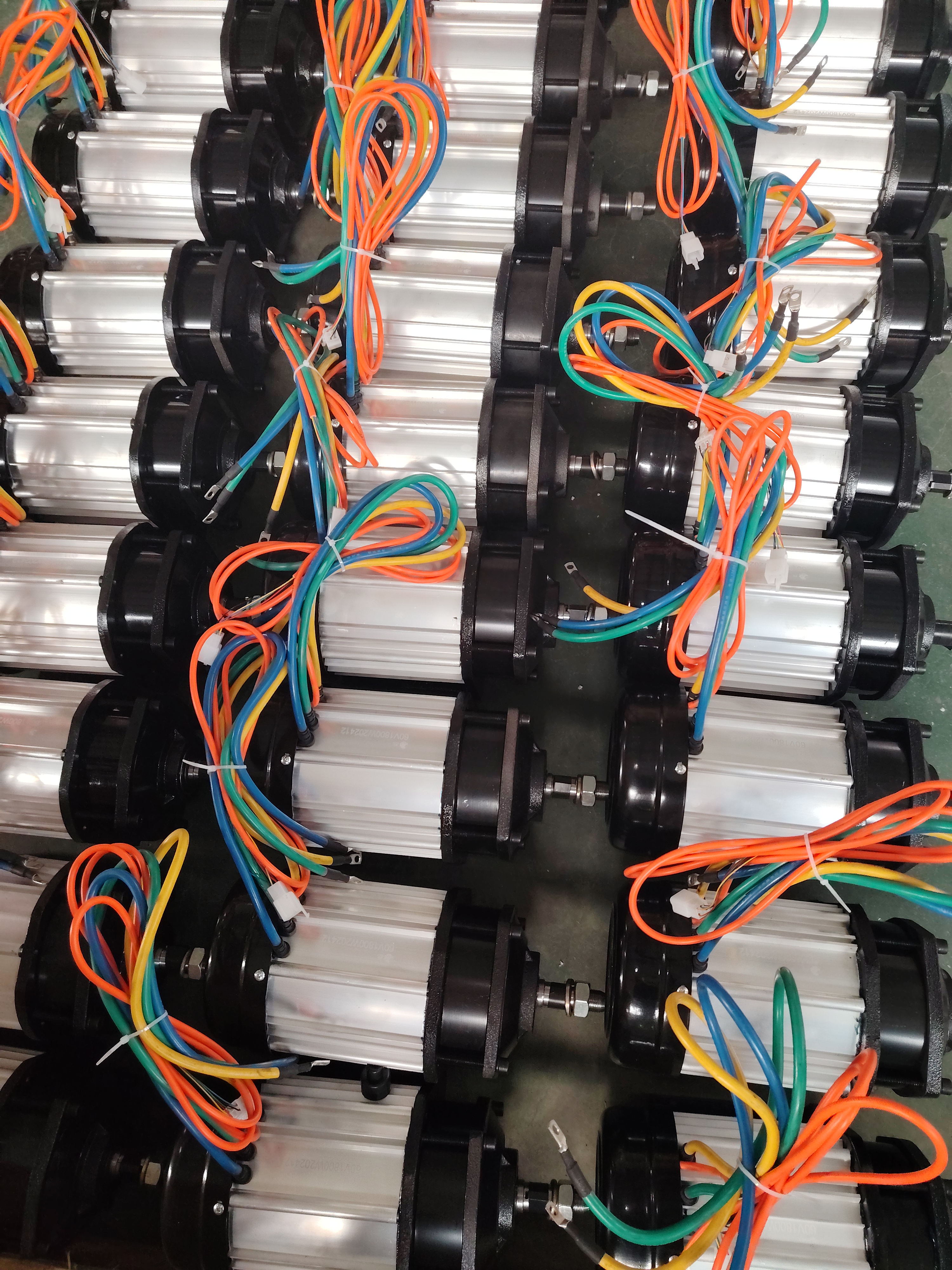

High Torque DC Geared Motor for Heavy Duty Applications

Key Selling Points

Factory Direct Pricing: Provides competitive pricing advantages for bulk purchases and wholesale orders.

Tailored for Heavy-Duty Use: Specifically engineered for electric tricycles and agricultural machinery, ensuring optimal performance in demanding environments.

Reliable Heavy-Load Performance: Delivers consistent high torque output even under full load, guaranteeing smooth starts and climbs.

Built to Last: Manufactured under strict quality control standards to ensure durability and an extended service life.

Flexible Customization: Offers comprehensive OEM & ODM solutions to meet specific client requirements.

🏭 Application scenarios

Industrial automation: driving conveyor belts, robotic arms, and packaging machinery.

Intelligent logistics: electric AGVs, sorting robots, and electric forklifts.

Other fields: electric tricycles, electric bicycles, textile machinery, climbing machines, etc.

High Torque Mid-Drive Brushless Motor

This type of motor typically features high torque, excellent climbing ability, and a robust structure, making it highly suitable for heavy loads and complex road conditions.

🛵 Electric Tricycle Sector

In the electric tricycle sector, high-power mid-drive geared motors are usually installed in the middle of the vehicle, directly driving the rear axle to provide strong starting and climbing power.

Electric Cargo Tricycles

Application: Used for urban logistics delivery, building materials transportation, or market deliveries.

Motor Advantages: Cargo tricycles often need to start or climb slopes while fully loaded. The mid-drive geared motor can provide extremely high low-speed torque, ensuring the vehicle can start easily even when fully loaded (e.g., hundreds of kilograms of cargo), while also being more energy-efficient.

Electric Passenger Tricycles

Application: Used for rural passenger transport, scenic area sightseeing, or shuttle services in specific areas.

Motor Advantages: Compared to ordinary hub motors, the mid-drive motor layout allows for a lower chassis, resulting in a smoother ride. Simultaneously, its powerful动力 can easily handle the weight of multiple passengers, ensuring driving safety.

Heavy-Duty Three-Wheel Vehicles

Application: Used for industrial handling, construction site transport, or large-tonnage cargo transport.

Motor Advantages: This is the most core application scenario for mid-drive geared motors. Ordinary motors are inadequate for multi-ton heavy vehicles. High-power mid-drive motors, combined with a reduction mechanism, can output massive traction force, meeting the dual demands of heavy-load climbing and high-speed driving.

🚜 Agricultural Machinery Sector

In agricultural scenarios, vehicles typically face muddy and rugged roads, requiring extremely high durability and explosive power from the motor.

Small Farm Tractors

Application: Used for field cultivation, plowing, or towing farm implements.

Motor Advantages: Continuous high-torque output is required during operation. The constant torque output characteristic of the mid-drive geared motor is very suitable for traction work. It can replace traditional internal combustion engines, achieving pollution-free and low-noise field operations.

Agricultural Transport Vehicles

Application: Used for transporting crops (such as corn, potatoes), fertilizers, or feed within farms.

Motor Advantages: Farmland roads are usually uneven and may have standing water or mud. Mid-drive motors typically have a high waterproof and dustproof rating, and a moderate ground clearance that makes them less prone to bumps. Their powerful动力 can easily handle climbing slopes and driving on poor roads when fully loaded with crops.

Feed Mixers and Farm Equipment

Application: Serving as the driving power for the chassis of feed mixers, or as a power source for stationary farm equipment (such as water pumps, threshers).

Motor Advantages: The mid-drive motor can divert power to the mixing device via belt or chain transmission. This “electromechanical integration” design allows the vehicle to function both as a transport vehicle and, when stopped, as the “power heart” for operating machinery.

Technical Specifications

| Parameter | Specification | Parameter | Specification |

| Model | 140 | Rated voltage | 48 v/60 v/72 v/80 v |

| rated voltage | 1500 W-4000 W | Rated speed | 640 rpm |

| peak torque | 1:5 | Rotor height | 70 mm~100 mm |

| Magnetic steel grade | 38 H | Motor color | silver, black |

| axis | Threaded Shaft | thermal classification | F |

| position sensor | Hall (5-pin) | Protection level | IP54 |

| Motor type | brushless motor | working system | S2 60min |

| motor shaft | Single key axis | polar pair | 4 |

Product working environment

| Storage temperature range | 40℃~85℃ |

| Working temperature range | Motor: -40 ℃~55 ℃ |

| humidity | 0~95% |

A:This motor is widely used in electric tricycles, agricultural machinery, and other heavy-duty electric vehicles requiring high torque and low-speed output.

A: Standard voltage options include 48V, 60V, 72V, and 80V. Custom voltage can be provided upon request.

A: Is this motor suitable for heavy load applications?

A: Yes. We offer OEM and ODM services, including power, voltage, gear ratio, and mounting customization.

A:The available power range is from 1500W to 4000W, suitable for different electric tricycle and agricultural machinery requirements.