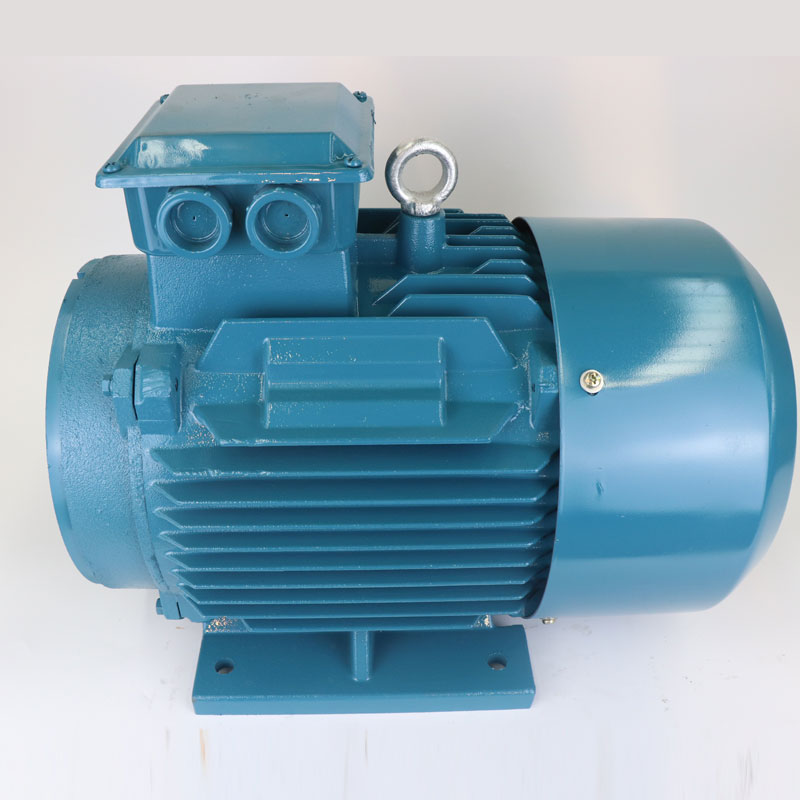

The YYB series direct coupled (inner shaft) oil pump dedicated motor designed for hydraulic systems eliminates the need for couplings and pump brackets, achieving perfect concentricity between the motor and oil pump.

Key Features of the Product

Direct drive, saving space

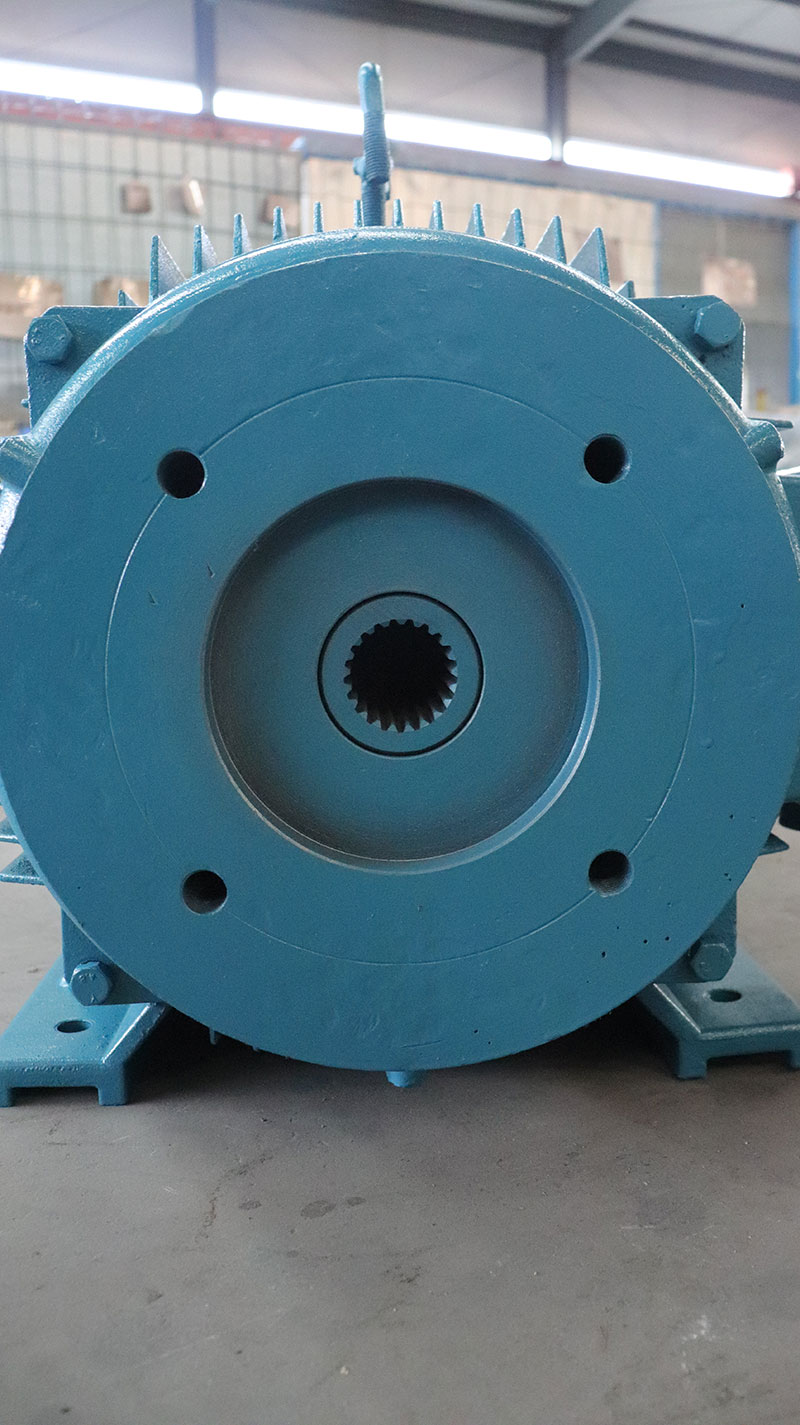

Adopting a unique “inner shaft” design, the motor rotor is directly mounted on the oil pump shaft. Compared with the traditional motor+coupling structure, the axial installation length is shortened by about 1/4, the structure is more compact, and equipment installation space is saved.

Silent and stable, maintenance free

Eliminating the alignment error of traditional connection methods, fundamentally solving the problems of high vibration and noise. The transmission efficiency is over 99%, running smoothly, effectively protecting the oil seal and preventing oil leakage.

High strength startup, overload optimization

Specially optimized for hydraulic pump operating conditions, with high starting torque, it can easily overcome the initial resistance of plunger pumps or gear pumps, and adapt to frequent starting and heavy load conditions.

Strong universality and easy installation

The flange interface and installation dimensions comply with international standards and can directly replace similar imported products. It is widely compatible with CB-B gear pumps, CY series plunger pumps, etc.

Piston Pump Oil Pump Motor

■ Hydraulic Power Unit for Piston Pump

■ Direct Drive Hydraulic Motor

■ CY14-1B Hydraulic Motor

■ High Pressure Hydraulic Pump Motor

■ 3 Phase Hydraulic Motor

| Parameter | Details | Remarks |

| Series model | YYB Series | Internal shaft direct connection dedicated motor| |

| Frame number | 90~280 | Corresponding power 0.37kW~90kW |

| Poles | 2P, 4P, 6P | Commonly used as 4-pole and 6-pole |

| Rated Voltage | 380V/415V/440V/480V | Supports customized voltage for multiple countries |

| Rated frequency | 50Hz/60Hz | | Broadband design |

| Connection | Y connection (≤ 3kW), Δ connection (>3kW) | Standard configuration |

| Insulation Class | Class F | Temperature rise assessment based on Class B or Class F |

| Protection level (IP) | IP54/IP55 | Dustproof and splash proof |

| Cooling method (IC) | IC411 | Self fan cooling |

| Duty | S1 (continuous work) | Continuous |